Steam maintenance的問題,透過圖書和論文來找解法和答案更準確安心。 我們找到下列包括賽程、直播線上看和比分戰績懶人包

Steam maintenance的問題,我們搜遍了碩博士論文和台灣出版的書籍,推薦Cattant, François寫的 Materials Ageing in Light-Water Reactors: Handbook of Destructive Assays 和Koester, Tony的 Steam & Diesel Locomotive Servicing Terminals: Layout Design and Planning都 可以從中找到所需的評價。

另外網站Predictive Maintenance of a Steam Turbine Video - MathWorks也說明:Learn how Sasol engineers implemented an end-to-end predictive maintenance program for steam turbines at the Sasol refinery.

這兩本書分別來自 和所出版 。

國立清華大學 工程與系統科學系 葉宗洸、王美雅所指導 施湘鈴的 水化學控制對於壓水式反應器一次側水環境 600合金與316L不銹鋼的應力腐蝕龜裂影響之研究 (2021),提出Steam maintenance關鍵因素是什麼,來自於應力腐蝕龜裂、鎳基600合金、316L不銹鋼、慢應變速率拉伸試驗、硼/鋰濃度、溶氫量。

而第二篇論文國立高雄科技大學 工學院工程科技博士班 王振華所指導 陸彥儒的 應用有限元素法發展高階適用性評估技術探討局部減薄缺陷幾何變異對承壓設備殘餘強度之影響 (2021),提出因為有 有限元素法、殘餘強度係數、塑性崩塌負載、適用性評估、局部減薄缺陷的重點而找出了 Steam maintenance的解答。

最後網站Turbine Steam Path: Maintenance and Repair - 博客來則補充:書名:Turbine Steam Path: Maintenance and Repair,語言:英文,ISBN:9780878147878,作者:Sanders, William P.,出版日期:2001/01/01,類別:自然科普.

Materials Ageing in Light-Water Reactors: Handbook of Destructive Assays

為了解決Steam maintenance 的問題,作者Cattant, François 這樣論述:

François Cattant graduated in chemical engineering in 1974 and joined Electricity of France (EDF) in 1975 as a chemical engineer in the Plant Operation Division working on the water and steam conditioning of power plants. Two years later, he moved to the hot laboratory at the Chinon Nuclear Power Pl

ant to examine failures and do root cause analysis of gas-cooled reactor components, including fuel. In 1980, he became the manager of a regional section for water and steam chemistry, chemical cleaning and non-destructive examination in fossil stations. He returned to the Chinon hot laboratory 3 ye

ars later where he continued to focus on failure root cause analysis of irradiated or contaminated components, monitoring of reactor pressure vessel (RPV) irradiation programs, examination of steam generator tubes, RPV head penetrations, split pins, pressurizer nozzles, valves, reactor cooling syste

m cast elbows, piping, fuel bundle and rods, rod cluster control assemblies, and much more.During 1995-1998, he was assigned as an expatriate engineer to the Nuclear Maintenance Applications Center of the Electric Power Research Institute in the USA where he worked on nuclear plant maintenance issue

s. While at EPRI, he also participated as an outside expert on the examination of Ringhals 3 retired steam generator. Returning back in France in 1998, François joined EDF R&D Materials and Mechanics of Components Department as a scientific advisor and senior engineer. His work involved chemistry, c

orrosion, and metallurgy with special attention to primary water chemistry, source term reduction, primary water corrosion, corrosion mitigation and repair, fuel cleaning and innovation strategies. He continued to serve as the EDF representative to the EPRI’s Materials Reliability Program. In this c

apacity, he participated in several destructive examinations such as North Anna Unit 2 RPV head penetrations, South Texas Project Unit 1 Bottom Mounted Instrumentation, Braidwood Unit 1 pressurizer heater #52 and San Onofre Unit 3 CEDM #64. From 2004 to 2008, he was the president of the "Materials,

Non-Destructive Testing and Chemistry" section of the "French Nuclear Energy Society", and from 2008 to 2009, he was in charge of the International Partnerships of the Materials Ageing Institute (MAI). Subsequent to his retirement from EDF in 2009, he was commissioned by the MAI to collect details a

nd produce summaries of destructive examinations performed on failures in light-water reactor components in France, USA, Japan, and Sweden which have now been compiled in this unique handbook. In 2014, the French Nuclear Energy Society awarded its "Grand Prix" to this "Handbook of Destructive Assays

". Ten years later, the MAI asked him to update this handbook, with both domestic and international recent field experience.

水化學控制對於壓水式反應器一次側水環境 600合金與316L不銹鋼的應力腐蝕龜裂影響之研究

為了解決Steam maintenance 的問題,作者施湘鈴 這樣論述:

鎳基合金600 (Alloy 600)與沃斯田鐵不銹鋼316L (SS 316L)為壓水式反應器(Pressurized Water Reactor, PWR)常見的結構組件材料,然而在電廠長期運轉下,結構組件腐蝕劣化問題層出不窮,如一次側冷卻水應力腐蝕龜裂(Primary Water Stress Corrosion Cracking, PWSCC)。為減緩腐蝕問題,各國電廠對於PWR進行了適當的水化學調控,如添加氫氣、控制pH值、硼酸濃度與氫氧化鋰濃度等。添加氫氣用以降低水環境因輻射分解反應而提高的氧化性,並減緩組件材料劣化,然而在目前EPRI規範的溶氫濃度25-50 cc⁄kg H2O

與運轉溫度320-360℃下,仍有PWSCC發生,因此各國核電廠考慮調整溶氫濃度至5 cc/kg H2O以下,或75 cc/kg H2O以上。此外,於水迴路中添加硼酸以控制中子反應度,添加氫氧化鋰則用於平衡水環境的pH值。但隨著燃料週期的燃耗,硼濃度逐漸下降,氫氧化鋰濃度也需有所調整。藉由溶氫(dissolved hydrogen, DH)濃度與pH值的調控,可使材料避開Ni/NiO的相轉換點,進而減緩PWSCC發生。因此本研究將探討燃料週期初期(Beginning of Cycle, BOC)與末期(End of Cycle, EOC)水環境在溶氫濃度降低至5 cc/kg H2O的條件下,對

於Alloy 600與SS 316L所造成的影響。本研究透過模擬PWR一次側水環境,對於Alloy 600與SS 316L進行慢應變速率拉伸試驗(Slow Strain Rate Test, SSRT)。實驗先將Alloy 600與SS 316L試棒進行固溶退火熱處理(SA)後,再分別進行單一階段時效處理(TT)與敏化熱處理(SEN)並預長氧化膜。而後模擬燃料週期初期與末期,在320℃與溶氫濃度為5 cc/kg H2O的水環境下進行SSRT試驗,分析材料應力腐蝕龜裂(Stress Corrosion Cracking, SCC)行為,並對於試棒破斷面與表面氧化膜形貌進行觀察與分析。實驗結果顯示

,對於Alloy 600而言,TT試棒在1200 ppm B + 3.5 ppm Li溶氫條件下展現最差的機械性質,但無論是除氧或溶氫環境,Alloy 600都表現出較低的SCC敏感性。而SS 316L SEN試棒在300 ppm B + 1 ppm Li溶氫條件下的最大抗拉強度(Ultimate Tensile Strength, UTS)與降伏強度(Yield Strength, YS)表現最差,然而實驗結果顯示溶氫可有效降低SEN試棒的SCC敏感性。Alloy 600表面氧化膜主要由尖晶石氧化物(spinel oxide) NiFe2O4、Cr2O3與NiO所構成,SS 316L的表面氧

化膜則以α-Fe2O3、γ-Fe2O3、尖晶石氧化物NiFe2O4與Fe3O4為主。

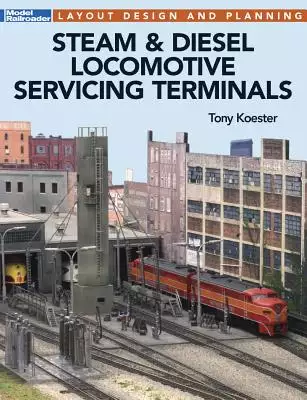

Steam & Diesel Locomotive Servicing Terminals: Layout Design and Planning

為了解決Steam maintenance 的問題,作者Koester, Tony 這樣論述:

This all-new book by Tony Koester explains how steam, diesel, and electric servicing facilities work, with details on the processes and equipment that can be replicated on model railroad layouts. The book includes: An overview of locomotive maintenance. Model railroad track plans and modeling exampl

es. Prototype photos of servicing terminals, roundhouses, turntables, sand houses and towers, and more.

應用有限元素法發展高階適用性評估技術探討局部減薄缺陷幾何變異對承壓設備殘餘強度之影響

為了解決Steam maintenance 的問題,作者陸彥儒 這樣論述:

承壓設備存有局部減薄時,不僅左右工廠的可操作性,同時也影響製程的潛在風險。適用性評估標準,發展至今,已是全世界廣泛使用的缺陷評估標準。其中又以API 579最負盛名。標準中定義殘餘強度係數(RSF)來評估受損結構的堪用性,並設定容許值。由於RSF計算並不容易,因此該標準依照保守程度、分析困難度,分成三個等級。其中最高等級的Level 3是使用數值分析方法。在過去,有許多研究文章,使用簡化作法(如:使用簡化的厚度輪廓、對稱分析、二維分析、子結構等),或者使用者自行定義RSF來分析堪用性。這些做法雖實務可行,但這並不符合標準作法,可能也會使分析結果過於樂觀。本研究將對前述常使使用的簡化作法進行分

析,並比較其差異。另外,本研究為了解前述各類項目如何影響RSF的精準度,以有限元素法為基礎,建立局部減薄缺陷的API 579 Level 3分析作法。本文有以下幾個重要成果及發現:1.建立API 579 Level 3評估程序;2.發現缺陷採用子模型,能維持分析精準度的同時,提升運算效率;3.外部LTA的實際殘餘強度,是低於相同尺寸的內部LTA的殘餘強度;4.由於LTA缺陷僅佔設備一小部分,因此通常被視為簡化的幾何形狀。但本篇的研究結果表明,所有簡化的厚度輪廓都會RSF,因應謹慎使用;5.通常認為較寬(即影響範圍較大)的減薄缺陷,被認為具有較低的RSF。但是,本研究表明,因應力集中效應,狹窄的

缺陷實際上更加危險。

想知道Steam maintenance更多一定要看下面主題

Steam maintenance的網路口碑排行榜

-

#1.Service Steam Maintenance Pty Ltd (Formerly Lend Lease ...

Resource Name: Service Steam Maintenance Pty Ltd (Formerly Lend Lease Services PL). Address: Level 4, 357 Collins Street MELBOURNE VIC 3000. 於 www1.worksafe.vic.gov.au -

#2.Steam down? Current problems and status.

View a list of the most recent times Steam was not loading or down, including the outage duration. The problem with Steam has been resolved. Total downtime: ... 於 downforeveryoneorjustme.com -

#3.Predictive Maintenance of a Steam Turbine Video - MathWorks

Learn how Sasol engineers implemented an end-to-end predictive maintenance program for steam turbines at the Sasol refinery. 於 www.mathworks.com -

#4.Turbine Steam Path: Maintenance and Repair - 博客來

書名:Turbine Steam Path: Maintenance and Repair,語言:英文,ISBN:9780878147878,作者:Sanders, William P.,出版日期:2001/01/01,類別:自然科普. 於 www.books.com.tw -

#5.General Maintenance of Steam Sterilisers - STS Health

General maintenance tips for the safe and effective use of your Steam Steriliser By the team at STS Health To ensure a high standard of performance ... 於 stshealth.com.au -

#6.Steam System Annual Maintenance - New England SteamWorks

We do annual steam system maintenance right. No shortcuts, ever. We have an 18-point inspection, cleaning, and tuning regimen that misses nothing. The other ... 於 newenglandsteamworks.com -

#7.Steam Systems 1 Learning System | Operation, Maintenance ...

Amatrol's Steam System Training System (950-SH1) introduces learners to the operation, installation, maintenance, and repair of steam systems. 於 amatrol.com -

#8.Steam Turbine Generator Maintenance Programs - Elliott Group

ESSENTIAL STEAM TURBINE MAINTENANCE. A properly maintained Elliott steam turbine generator (STG) can operate reliably and efficiently for decades. 於 www.elliott-turbo.com -

#9.When does Steam maintenance end? Exact times - Apps UK

Steam's routine maintenance sessions are scheduled to occur every Tuesday. Such routine maintenance sessions work in preventing any major issues ... 於 apps.uk -

#10.Inspect and Repair Steam Traps, Energy Tips

maintenance program, leaking traps should account for less than 5% of the trap population. If your steam distribution system includes more than 500 traps, a. 於 www.energy.gov -

#11.Truesteam or Steam branded Humidfier Maintenance

For a TrueSteam or Steam branded humidifier you should remove the bucket and clean the bucket of debris and scale using vinegar or CLR. 於 www.honeywellhome.com -

#12.Steam Cleaning Machine Maintenance - OspreyDeepclean

Maintenance for dry steam cleaning machines | Experts in machine maintenance | Contact us today via [email protected] or calling 01242 513123 ... 於 ospreydc.com -

#13.Elden Ring Servers Back Online for Steam and PlayStation ...

Earlier this morning, the Elden Ring Twitter account announced that multiplayer server maintenance would begin on March 23 at 1am Pacific / 8am ... 於 www.ign.com -

#14.Steam Drum - improved performance | Orion instruments

Steam leakage as well as maintenance costs associated with traditional sight gauges in continual operation. SOLUTION. Magnetrol® technologies eliminate the ... 於 www.orioninstruments.com -

#15.Steam service error the Steam service on your machine ...

Steam service error the Steam service on your machine requires some maintenance. The Geek Page. The Geek Page. 78.9K subscribers. Subscribe. 於 www.youtube.com -

#16.When Is Steam Maintenance? [HINT: Tuesdays] - PC Strike

Steam conducts scheduled weekly maintenance on Tuesdays that begins sometime between 1 PM and 3 PM Pacific Time. It lasts for approximately ... 於 pcstrike.com -

#17.Steam is worse - weekly "maintenance" on Tuesday evening ...

Steam is worse - weekly "maintenance" on Tuesday evening, where everyone is disconnected for ~10-20 minutes. It's common knowledge not to play at that time ... 於 news.ycombinator.com -

#18.How to Clean and Descale Steam Iron - Panasonic Middle East

By properly descaling the calc, the iron can be used for a long time. Here we introduce Panasonic's original maintenance methods for irons and how to prevent ... 於 www.panasonic.com -

#19.Steam Service Error: Steam Service requires some maintenance

Fix Steam Service Error, The Steam Service on your machine requires some maintenance message on your Windows PC by following these ... 於 www.thewindowsclub.com -

#20.Operation and Maintenance Engineering - Steam Plant - LATTC

Maintenance and repair workers keep records of their work. The “Certified Steam Boiler License” is a specialized certification required for many maintenance ... 於 www.lattc.edu -

#21.Steam Trap Maintenance-Prioritizing Model Based on Big Data

Steam traps in large facilities need continuous maintenance to prevent corrosion and other damage that could pose a considerable threat to a ... 於 www.ncbi.nlm.nih.gov -

#22.Steam Boiler Preventative Maintenance Musts - Chardon Labs

Due to their importance, preventative maintenance (PM) is necessary for all industrial steam boilers if managers want to maximize uptime and minimize repair ... 於 www.chardonlabs.com -

#23.Steam Trap Rx-preventive Maintenance - Google 圖書結果

D201.27 : 85-15 fdoc D 201.27 : 85-15 Steam trap rx 2 0000 004 407 553 DE ... Sheet tells you how to set up a steam trap preventive maintenance program . 於 books.google.com.tw -

#24.STEAM Consultancy

As a respected asset management partner we offer you a team of enthusiastic consultants and maintenance engineers. Our services. I van Implementatie ... 於 www.steamconsultancy.com -

#25.APM Steam: Steam Trap and Heat Exchanger Experts

Steam and Energy Efficiency Specialists. Save energy and money by letting our experts develop a comprehensive steam systems maintenance program for your ... 於 apmsteam.com -

#26.Steam Turbine Maintenance and Repair Tool System

Complete Line of Hand, Power & Machine Tools and Tool Kits for Military, Business, Commercial, Industrial, and Government. 於 www.kippertool.com -

#27.Steam System Risk Mitigation (SSRM®) - TLV

The assessment results provided a quantitative basis for prioritizing maintenance resources, while highlighting the current high-risk equipment. 於 www2.tlv.com -

#28.High-Pressure Steam Boiler Preventative Maintenance

Do you have a comprehensive maintenance plan for your high pressure steam boilers and related equipment? Are you doing everything you can to ... 於 powerhouse-combustion.com -

#29.Spirax Sarco - Regular testing and maintenance of your...

fully optimised steam trap population. 🛠️ Reducing the risk of injury and equipment damage from waterhammer. Improved processes and ... 於 www.facebook.com -

#30.Destiny Server and Update Status - Bungie Help

Please see below for information on upcoming Server Maintenance or Destiny ... who encounter issues installing Destiny 2 on Steam should visit Valves Update ... 於 help.bungie.net -

#31.Steam Cleaner Maintenance | Descaling a Steam Mop

Keep your machine running at its best with our steam cleaner maintenance tips. Descaling a steam mop is one of many vital aspects of cleaning a steamer. 於 www.achooallergy.com -

#32.Industrial Steam Boiler System, Operation and Maintenance

Hence, steam generation with the associated operation and maintenance of steam plants is a specialized area. This Zoe training course will empower attendees ... 於 zoetalentsolutions.com -

#33.(PDF) Classification Model for predictive Maintenance of ...

PDF | With 35000 small steam sterilisers in the German market, after‐sales service and maintenance are critical issues for manufacturers and ... 於 www.researchgate.net -

#34.Steam Maintenance and Efficiency | Con Edison

Steam Maintenance and Efficiency · 1. Storage of Thermal Energy in Existing Mechanical systems (STEEMs) · 2. Preheat the Building · 3. Stagger Fan Start Ups in the ... 於 www.coned.com -

#35.Steam servers are currently undergoing routine maintenance

Routine maintenance during peak hours. wtf Valve? Why not schedule it when the least amount of people are playing??? 於 www.reddit.com -

#36.49 CFR Part 230 -- Steam Locomotive Inspection and ... - eCFR

Person or entity which operates, but which does not necessarily own, one or more steam locomotives. This term means, for purposes of inspection and maintenance ... 於 www.ecfr.gov -

#37.Trip your turbine troubles: Optimize the reliability of steam ...

This requires effective collecting leg design, proper selection, placement and maintenance of condensate discharge locations (CDLs)—including the steam traps ... 於 www.hydrocarbonprocessing.com -

#38.Recommended maintenance and inspection for low pressure ...

The BC Safety Authority recommends that owners of low pressure steam boilers put into practice a routine maintenance program and establish a regular, periodic ... 於 www.technicalsafetybc.ca -

#39.Steam Boiler Service & Maintenance | Queensland

Get your steam boiler repaired & serviced by the team at East Coast Steam today! ... Boilers in Great Shape: Australia-Wide Boiler Service and Maintenance ... 於 www.eastcoaststeam.com.au -

#40.Taking the Steam Out of Wet Area Maintenance

Dirt, mold, mildew and bacteria can make your steam room, sauna and showers ... It can be easy to let steam room and sauna maintenance fall by the wayside. 於 www.athleticbusiness.com -

#41.Implementation of Predictive Maintenance strategy for a steam ...

Check out the case study of the implementation of the Predictive Maintenance strategy for a steam turbine. See the challenges and benefits ... 於 reliasol.ai -

#42.Sea of Thieves - Game Status

Sea of Thieves is currently down for maintenance. Please see our social channels ... Find out how to install Sea of Thieves on Windows 10/11 or via Steam. 於 status.seaofthieves.com -

#43.Process Steam Systems: A Practical Guide for Operators, ...

workers need to take advantage of every steam system outage and be prepared to ... maintenance has been performed on the associated steam system equipment. 於 books.google.com.tw -

#44.Steam Turbine Maintenance: How Portable Machine Tools ...

What can go wrong with steam turbines? · Figure 1. · Figure 2: Failure failure types ranked by frequency and severity. · Maintenance Programmes. 於 blog.enerpac.com -

#45.Inspection and Maintenance Standards for Steam Locomotives

Inspection and Maintenance Standards for Steam Locomotives. Document Series. Final Rule. FRA Docket Number. TBD. Subject Locomotive Standards (Safety ... 於 railroads.dot.gov -

#46.Best Practices For Industrial Steam Boiler Maintenance

Industrial boiler maintenance is critical for ensuring the optimal efficiency and safety of your facility. Because steam boiler and heating system problems ... 於 miuraboiler.com -

#47.Lelit Bianca: Steam Boiler Fill Solenoid Inspection and Cleaning

Steam /Hot Water Maintenance ... Use these instructions to check your machine's steam boiler fill solenoid and clear it of any debris that may be preventing ... 於 support.clivecoffee.com -

#48.How to fix Steam Service Error on Windows?

The Steam Service on your machine requires some maintenance. This service helps Steam install or update games, enables anti-cheat detection ... 於 ugetfix.com -

#49.Top 3 Maintenance Tips for Your Steam Generator

Top 3 Steam Shower Generator Maintenance Tips from MrSteam · 2. Add a water softener system to your home · 3. Do a manual cleaning of your steam ... 於 blog.mrsteam.com -

#50.Engineering Shop Supervisor at USC

Experience utilizing Personal Computers and Computerized Maintenance Management Systems. Steam Engineer – 500 HP License (or greater) issued ... 於 usccareers.usc.edu -

#51.Steam Server Status: Is Steam Down Right Now? Answered

Valve advises that Steam maintenance times are typically less than an hour. In these circumstances, it's best to just wait things out for a short time before ... 於 www.gameskinny.com -

#52.Daily Steam Boiler Maintenance in the Boiler Room - Ware Inc.

Boiler Maintenance Checklist. Do a bottom boiler blowdown. Blow down the water column. Record the boiler's pressure and temperature in a daily ... 於 www.wareinc.com -

#53.Steam 停機時間和伺服器維護

伺服器停機的原因有時是進行維護, 好比修補軟體、修正安全性問題、更新作業系統、更新驅動程式,或安裝新硬體。 以上行為並不會帶來新的功能,卻能讓Steam 繼續穩定、有 ... 於 help.steampowered.com -

#54.Common Steam Autoclave Maintenance Questions, Answered

Routine maintenance is essential in order to ensure the productivity, safety, and longevity of your steam autoclave. 於 consteril.com -

#55.Info - TOP | eFootball Official Site

eFootball™ Coins Purchase Issue. 16/02/2023. PS5; PS4; XboxOne; Xbox X|S; Steam; Windows10 · Maintenance. Additional ... 於 www.konami.com -

#56.Road Maintenance Simulator Price history - SteamDB

For your work you will have unique vehicles and various usable tools at your disposal. Road Maintenance Simulator Steam charts, data, update history. 於 steamdb.info -

#57.Steam Generator Maintenance Blow-Down procedure (DRAIN ...

Monthly Maintenance: General review of the Steam Generator operating pressure should be conducted regularly during a standard Sterilizing Cycle to. 於 www.priorclave.com -

#58.Steam Status (Unofficial) (@SteamStatus) / Twitter

Steam Maintenance 15:40 PDT There have been an increased amount of page views on Steam Status in the past hour, this could indicate an issue with Steam. 於 twitter.com -

#59.Top 10 tips to maintain your steam system safely and efficiently

Regular testing and maintenance is crucial to ensure that the steam traps function correctly. Further losses can come from the pipework itself and this should ... 於 www.processindustryforum.com -

#60.Steamo I Expert en maintenance multitechnique I France

Steamo, un expert en maintenance multitechnique du groupe Armonia. 於 www.steamo.fr -

#61.Steam Maintenance Decision Guidance for the Downstream ...

How does the weather affect steam cushion within an O&G plant, and what ... Steam Maintenance Decision Guidance for the Downstream Oil and Gas Industry. 於 www.stormgeo.com -

#62.Is Steam Down? How To Check The Server Status - EarlyGame

Steam maintenance occurs when the company needs to update or make changes to their servers, and it's usually scheduled in advance. 於 earlygame.com -

#63.Steam Maintenance Schedule: How Long Is The Duration?

How long will Steam be down for Maintenance? ... If a maintenance period is planned, then it should last for about an hour or less. But if there's ... 於 gamertweak.com -

#64.Maintenance and Overhaul of Steam Turbines | IMIA

Maintenance and Overhaul of Steam Turbines ... John Latcovich, Hartford Steam Boiler (Chairman) ... Steam Turbine Availability and Failure Experience. 於 www.imia.com -

#65.Steam Turbine Maintenance | JFE Technos Co., Ltd.

Steam Turbine Maintenance. Steam turbines, which are essential for a stable energy supply, are driven by high temperature, high pressure steam, ... 於 www.jfe-technos.co.jp -

#66.Steam Trap Performance Assessment: Advanced Technologies for ...

Steam trap proactive maintenance program cost estimates.3 Minimal. blowdown requirement and associated energy and water losses. Even where condensate is ... 於 books.google.com.tw -

#67.Steam down? Current network status and problems

Real-time network status for Steam. Can't play your games? Is the service down? Here you see what is going on. 於 downdetector.com -

#68.Steam Locomotive Construction and Maintenance - Google 圖書結果

... volume to the primer on The Steam Railway Locomotive in this series. ... STEAM LOCOMOTIVE CONSTRUCTION AND MAINTENANCE Table of Contents CHAPTER I. 於 books.google.com.tw -

#69.Steam current server status and maintenance schedule

Basic routine maintenance on Steam servers is performed on Tuesdays, with some outages occurring generally around the afternoon to evening times ... 於 www.shacknews.com -

#70.Maintenance | Phantasy Star Online 2 New Genesis Official Site

News; Maintenance. Maintenance. Latest Articles · Announcements · Maintenance ... Xbox One; Windows; Steam; Epic Games; PlayStation® family PlayStation®4. 於 pso2.com -

#71.Steam plant operation improvement - GloMEEP

Experience has shown that there is an improvement potential for boiler operation in terms of general use and maintenance of the boiler and steam plant ... 於 glomeep.imo.org -

#72.Preventive Maintenance of Steam Turbine used in Thermal ...

Preventive Maintenance of Steam Turbine used in. Thermal Power Plant by Reliability Investigation and FMEA. Satyendra Dhurvey1, Pradeep Kumar Soni2. 於 www.ijsr.net -

#73.Tuesday's server reset/maintenance :: Steam Discussions

Why its this still a thing? Other services like xbox or playstation have backup servers when they restart the main servers. 於 steamcommunity.com -

#74.Steam遊戲平台顧客關係維繫之研究 - 博碩士論文網

本研究針對台灣地區對Steam遊戲平台有經驗之使用者作為研究對象,採用網路問卷, ... A Study on Customer Relationship Maintenance of The Steam Game Platform ... 於 ndltd.ncl.edu.tw -

#75.5 tips to effectively maintain your steam system

Steam systems are generally efficient and reliable. ... and in-house assets and maintenance personnel facing increasing demands on their ... 於 www.plantengineering.com -

#76.Common Preventative Maintenance For A Steam Trap - UpKeep

Preventive maintenance checklists for steam traps include items about temperature, pressure, condensation and equipment functioning. 於 www.upkeep.com -

#77.Lost Light - A Realistic War Experience Like No Other

加入萤火虫特遣小队,你准备好了吗? ; Notice. 05-17. Maintenance Update - May 18. Patch notes for the maintenance conducted on May 18 ; Notice. 05-10. Maintenance ... 於 www.lostlight.game -

#78.Steam Trap Maintenance Solutions from ERIKS

Too many industrial sites still have steam traps which are wrong for their application. An expert Steam Trap Survey from ERIKS can reveal problems and offer ... 於 eriks.co.uk -

#79.Steam Plant Maintenance City and Guilds Accredited

Start Date Duration Location Register 22/05/2023 4 Days Cheltenham Register 05/06/2023 4 Days Cheltenham Register 19/06/2023 4 Days Cheltenham Register 於 www.spiraxsarco.com -

#80.Steam Tuesday Maintenance: All You Need to Know

Steam's servers undergo routine maintenance every Tuesday. That's why Steam often goes down on Tuesdays. The good news is that the service should go back online ... 於 bestgamingtips.com -

#81.Hi-Rez Studios, Inc Status

In progress - Scheduled maintenance is currently in progress. We will provide updates as necessary. May 17 , 13:45 EDT. Scheduled - We are performing a server ... 於 status.hirezstudios.com -

#82.Steam Trap Testing and Maintenance

Detecting Failed Steam Traps using Ultrasound · Minimum Steam Loss; · Maximum Transfer of Heat; · Timely removal of condensable gasses; · Zero Unplanned Downtime ... 於 sdtultrasound.com -

#83.Steam Sterilizers Service Plans - Getinge

Protect your investment and keep your Getinge steam sterilizer operating at peak efficiency with a ... Annual preventative maintenance parts (if required). 於 www2.getinge.com -

#84.Is Steam Down?

If it is a Tuesday at around 16:00 Pacific time then it is probably scheduled maintenance, otherwise I don't know. What if I get the message "The Steam servers ... 於 www.issteamdown.com -

#85.Steam down - Server status update for Steam downtime ...

STEAM users complain about not being able to connect to the PC gaming platform, which appears to be undergoing routine maintenance. 於 www.express.co.uk -

#86.CS2 and CS:GO Steam Status - CSGO Database

Rest of World · Steam Server Maintenance occurs every Tuesday and primarily affects the Steam Community servers which results in delays for the Player ... 於 www.csgodatabase.com -

#87.Steam trap monitoring enables predictive maintenance - ISA

Monitoring identifies steam traps and downstream equipment issues to maintain plant efficiency. By Tom Bass. Steam distribution systems support ... 於 www.isa.org -

#88.Care and Maintenance of Steam Systems - BOMI International

Care and Maintenance of Steam Systems. February 2010 ... heating or power, the steam condenses and is returned to the boiler through the condensate lines. 於 www.bomi.org -

#89.Maintenance Strategies for Steam Turbines - LinkedIn

Maintenance is an essential part of keeping steam turbines operating efficiently and reliably. Here are some common maintenance strategies ... 於 www.linkedin.com -

#90.Important Notice for Steam Players Using DirectInput Controllers

If your controller (primarily PlayStation®4 controllers, arcade sticks, etc.) employs DirectInput, launching STREET FIGHTER V after applying the above update ... 於 game.capcom.com -

#91.Steam Turbine Maintenance and Repairs | GE Steam Power

GE is committed to your organization's efficiency and future success by delivering new steam turbine repair and maintenance programs. Learn more today. 於 www.ge.com -

#92.Commissioning , maintenance and repair of steam turbines

We specialize in turbines, commissioning, laser alignment, maintenance and repair of steam turbines. We offer a 24 hour service for steam turbines. 於 www.k-kturboservice.de -

#93.What is Steam Maintenance Tuesday and How Long Does it ...

Steam pointed out in an official post that downtime during maintenance would generally be under an hour in most cases. In case Steam plans an ... 於 windowsreport.com -

#94.Steam Dragon Setup and Maintenance

The SteamDragon™ has been engineered to provide thousands of steam cycles with minimum problems and maintenance. As long as distilled water is ... 於 blog.esslinger.com -

#95.How long does Steam maintenance take? Steam ... - Gamepur

Scheduled maintenance on Steam doesn't take more than one hour to complete. However, if the servers are down for an unscheduled reason, ... 於 www.gamepur.com -

#96.Is Steam down? - when is the next Steam maintenance? - WePC

How long are Steam servers down? Usually, the maintenance takes any time between 30-60 minutes. So you could be out waiting for quite some time ... 於 www.wepc.com -

#97.Hot Water Boiler Room Safety Checklist | Weekly/Monthly ...

Boiler Daily Log Book: Boiler Preventive Maintenance Schedule Checklist | Steam Boiler Inspection Book | Hot Water Boiler Room Safety Checklist ... 於 www.amazon.ca -

#98.Steam Status · Is Steam Down?

Displays status of Steam client, Steam store, Steam community, Dota 2, TF2 and Counter-Strike. 於 steamstat.us